Designed to handle severe frost and rock removal jobs

Nominated for the 2006 NOVA Award

Made with Hardox 400 or 450

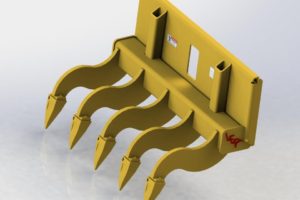

Below is shown a Multi-Ripper Bucket with ESCO Teeth, also available

Below is one of the original designs of the Multi-Ripper Bucket

for a larger excavator:

Designed to handle severe frost and rock removal jobs, the Leading Edge Attachments, Inc.’s patented Multi-Ripper Bucket™ is an engineering breakthrough that works on the same principal as the award winning Multi-Ripper! Just like the Multi-Ripper, the Multi-Ripper Bucket can be used for a wide range of tough material applications such as excavating frozen ground, coral, sandstone, limestone, shale, decomposed granite and caliche. This unique patent pending design has demonstrated that it can dig faster than using a single pointed ripper tooth. Under severe digging conditions, the performance also exceeds other designs of frost, rock, Vee-trenching, DigNRip™ Buckets, or other styles of ripper bucket combinations. The Multi-Ripper Bucket is the absolute best and most productive ripper bucket combination available on the market (with the exeption of our Hi-Cap Multi-Ripper Bucket and our Multi-DigNRip Hi-Cap Bucket)! The new Multi-Ripper Bucket is available to fit any excavator or backhoe above 11,000 pounds. Patented in North America and in many other countries.

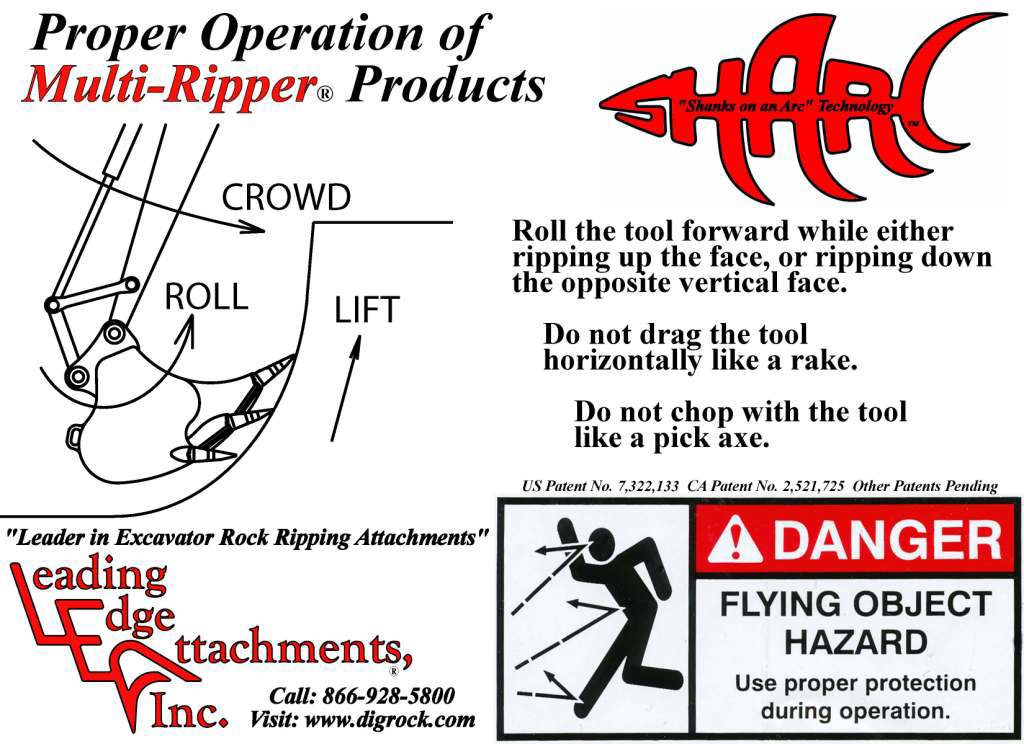

The Multi-Ripper Bucket is similar to the Multi-Ripper and utilizes the patent pending SharkTM Technology which results in the unit functioning similarly to that of a trencher except it uses the hydraulic excavator rolling action to rip. The staggered ripper teeth fracture the substrate in sequential order. No two ripper teeth align with each other, so that the maximum breakout force is applied sequentially to each tooth. The distance from the excavator stick pivot to the tooth tips is also shorter than the standard bucket for the machine. The shorter distance actually multiplies the tooth tip force. The castle top shape grooves cut by the front ripper teeth facilitates the fracturing process of the next swipe. The rolling of the Multi-Ripper Bucket, by extending the bucket cylinder, always provides the full multiplied breakout force individually on each tooth so that the substrate is ripped out by each individual tooth lifting action. The result is a relatively flat trench bottom due to the fact that the ripper tooth tips all lie on a constant radius with a center of rotation that is close to the tractor loader backhoe or hydraulic excavator “dipper stick” bucket pivot. Due to the leading edges and the back-sheets, the Multi-Ripper Bucket can also scoop material, thus eliminating the need to switch back to a bucket for clean up. The Multi-Ripper Bucket will function, and greatly exceed, any application, or material, that a single pointed ripper tooth can be used for.

With the stick in the near vertical position, use a combination of bucket and crowd cylinder functions while providing boom cylinder down pressure. The bucket cylinder action provides the greatest force while the stick sweeps. Since no two teeth are in alignment, when the Multi-Ripper Bucket is rolled, each tooth engages separately so that each tooth fractures the groove cut by the preceding tooth. Roll the Multi-Ripper Bucket completely as the stick is being moved so that all teeth have engaged the material. The Multi-Ripper Bucket is to be rolled as the stick is moved, thus causing a very powerful, fast and effective ripping and scooping motion that is easy on the machine and operator and is highly effective.

Leave a Reply

Your email is safe with us.