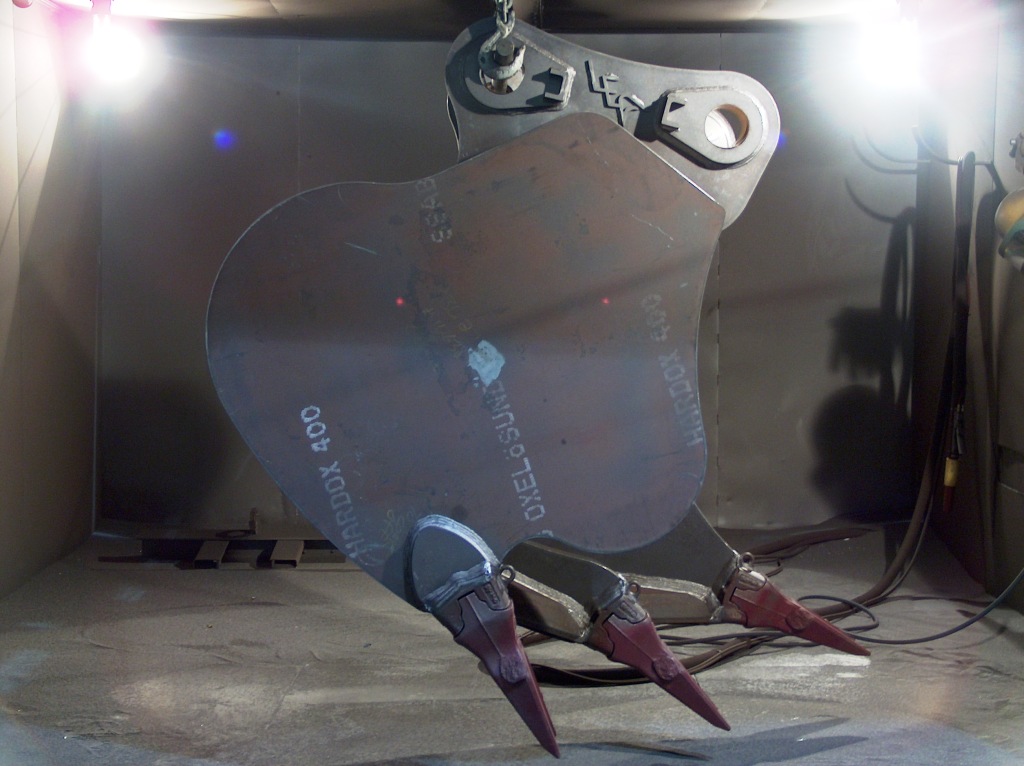

Hi-Cap MRB

Made with Hardox 400 or 450

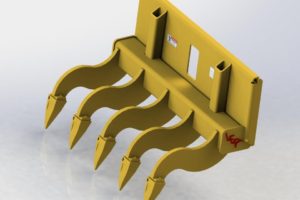

Standard MRB

The following shows some of these powerful buckets being built.

Note the Swedish HARDOX 400 steel.

An engineering excavator rock bucket breakthrough that works on the same principal as the award-winning Multi-Ripper(R)! Just like the patented Multi-Ripper, the patented Multi-Ripper Bucket is an excavator rock bucket that can be used for a wide range of tough material applications such as excavating frozen ground, coral, sandstone, limestone, shale, decomposed granite and caliche. This unique patent pending design has demonstrated that it can dig 7 to 10 times faster than using a single pointed ripper tooth. Under severe digging conditions, the performance also exceeds other designs of frost, rock, Vee-trenching, DigNRip™ Buckets, or other styles of rock bucket / ripper bucket combinations 2 to 1. The Multi-Ripper Bucket is the absolute best and most productive ripper rock bucket combination available on the market with the exception of our Multi-DigNRip Hi-Cap Bucket which has added shanks on the back! The new Multi-Ripper Bucket is available to fit any excavator or backhoe above 6,000 pounds. Patented in North America and many other countries.

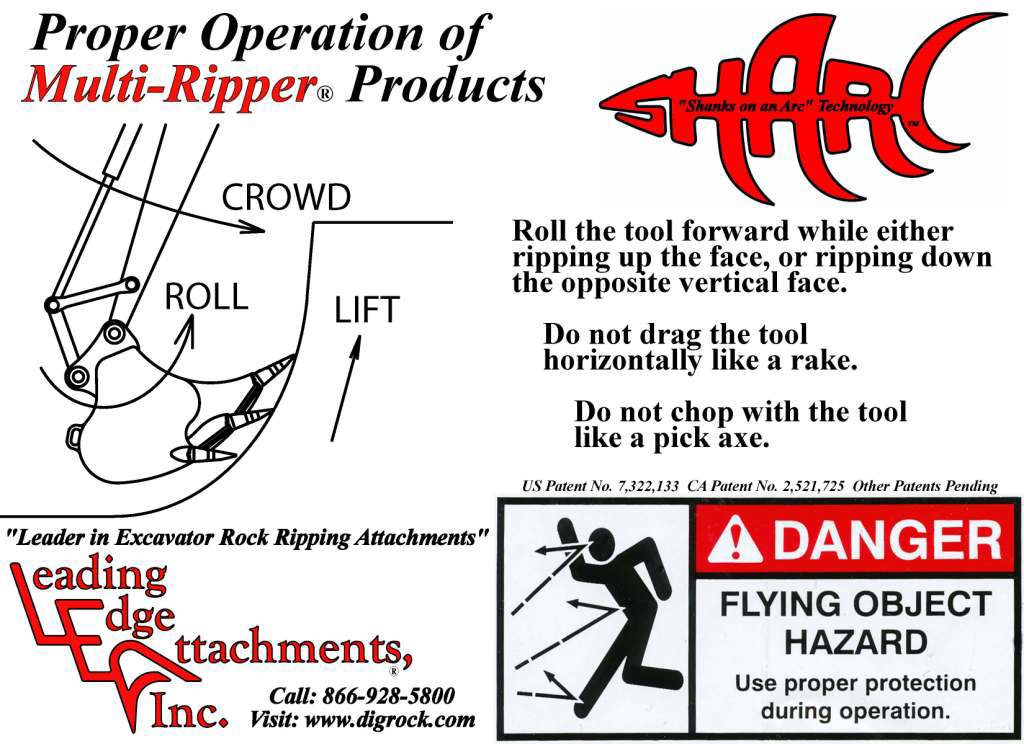

The Multi-Ripper Bucket is similar to the Multi-Ripper and utilizes the patented SharkTM Technology which results in the unit functioning similarly to that of a trencher except it uses the hydraulic excavator rolling action to rip. The staggered ripper teeth fracture the substrate in sequential order. No two ripper teeth align with each other, so that the maximum breakout force is applied sequentially to each tooth. The distance from the excavator stick pivot to the tooth tips is also shorter than the standard bucket for the machine. The shorter distance actually multiplies the tooth tip force. The castle top shape grooves cut by the front ripper teeth facilitates the fracturing process of the next swipe. The rolling of the Multi-Ripper Bucket, by extending the bucket cylinder, always provides the full multiplied breakout force individually on each tooth so that the substrate is ripped out by each individual tooth lifting action. The result is a relatively flat trench bottom due to the fact that the ripper tooth tips all lie on a constant radius with a center of rotation that is close to the tractor loader backhoe or hydraulic excavator “dipper stick” bucket pivot. Due to the leading edges and the back-sheets, the Multi-Ripper Bucket can also scoop material, thus eliminating the need to switch back to a bucket for clean up. The Multi-Ripper Bucket will function, and greatly exceed, any application, or material, that a single pointed ripper tooth can be used for.

With the stick in the near vertical position, use a combination of bucket and crowd cylinder functions while providing boom cylinder down pressure. The bucket cylinder action provides the greatest force while the stick sweeps. Since no two teeth are in alignment, when the Multi-Ripper Bucket is rolled, each tooth engages separately so that each tooth fractures the groove cut by the preceding tooth. Roll the Multi-Ripper Bucket completely as the stick is being moved so that all teeth have engaged the material. The Multi-Ripper Bucket is to be rolled as the stick is moved, thus causing a very powerful, fast and effective ripping and scooping motion that is easy on the machine and operator and is highly effective.

because it is more like a ripper than a bucket! The Multi-Ripper Bucket has only three teeth that engage one tooth at a time. There is no other bucket that engages throughout its travel while engaging one tooth at a time. The DigNRip style has teeth on the corners of the bucket that engage at the same time and thus effectively cut down on the ripping force by a factor of two! No other bucket has this ripping ability!

Not only are the forces higher and there are more teeth to rip, but there is now a way to scoop the material out of the way to expose virgin material. The process of switching back and forth from the ripper to the bucket can be time consuming in some applications. It is obvious that the Multi-Ripper Bucket is at least three times faster than a single pointed ripper because it has three teeth; however, it is actually 10 times faster because of the force multiplication, the multiple teeth, and its ability to scoop the material out of the way.

Before the Multi-Ripper Bucket was available, operators had to rip with a single pointed ripper with one excavator, and load with the other. In order to keep the flow moving, the ripping excavator would rip a whole portion of the sandstone quarry at a time. The single pointed ripper would be hard on the machine, produce a lot of sand and, if it rained before they had a chance to load, the sandstone would absorb moisture, which would gum-up their crushing plant. Since their new MR Bucket allows them to rip and scoop at the same time, they only need to use one excavator. It also allows them to load as soon as the material is ripped so the material doesn’t absorb as much moisture. Since the Multi-Ripper Bucket is designed with three shanks on an arc, the ripping motion is smooth and considerably easier on the machine and operator. Also, since they are loading as they rip, there is less sand produced from re-handling the rock. Another advantage of the MR Bucket is that they are able to remove the rock as it is being ripped. This helps considerably in their operation because they can see and keep a level pit floor to work from as they move along, so no other equipment is needed.

Leave a Reply

Your email is safe with us.