Made with Hardox 400 or 450

Multi-DigNRip V-Raptor Bucket

Designed to handle the more severe frost and rock removal jobs

The High Production Multi-DigNRip Bucket

Designed to handle the more severe frost and rock removal jobs, the Leading Edge Attachments, Inc.’s DigNRip Bucket can be used for a wide range of tough material applications such as excavating frozen ground, coral, sandstone, limestone, shale and caliche. This type of unique design has demonstrated that it can dig several times faster than using a single pointed ripper tooth and a bucket. Under severe digging conditions the performance exceeds other designs of frost or rock buckets. The DigNRip bucket is available for all backhoes and excavators from the 11,000 lb. to 220,000 lb. excavator class.

The LEA DigNRip bucket functions similarly to that of a trencher except while the back of the bucket is ripping the front of the bucket is scooping loosened material. You are doing two functions at once, ripping and digging!

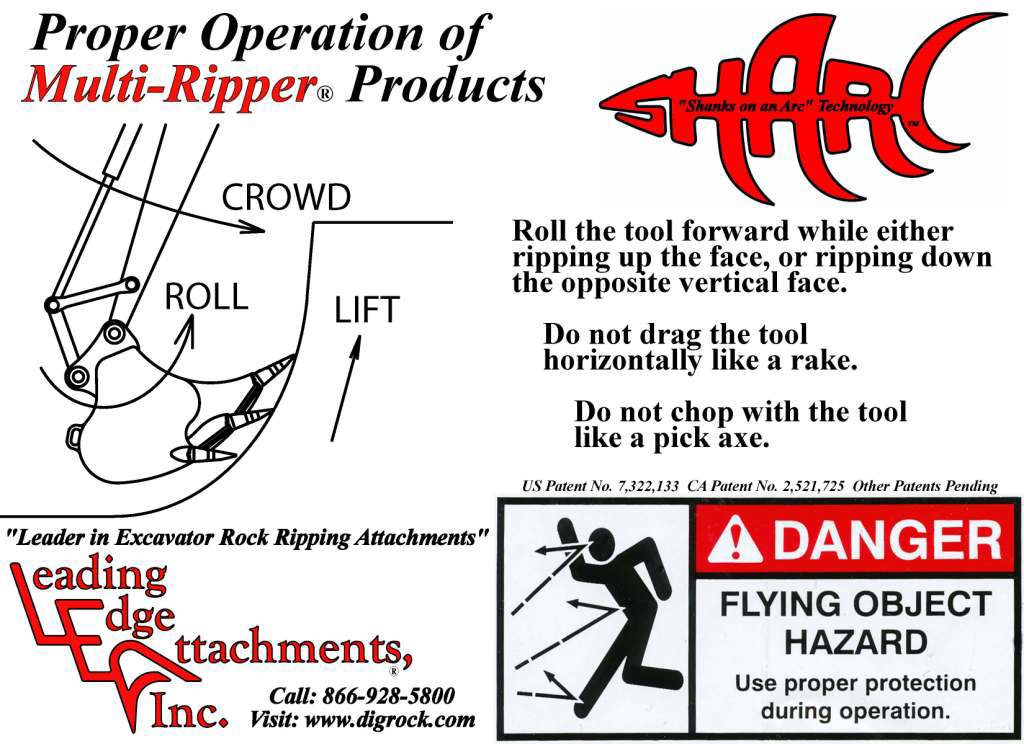

The ripper teeth in the rear fractures the substrate in sequential order. No two ripper teeth align with each other, so that the maximum breakout force is applied sequentially to each tooth. The castle top shape grooves cut by the front ripper teeth facilitates the fracturing process of the rear teeth. The rolling of the bucket process, by extending the bucket cylinder, always provides the full breakout force so that the substrate is ripped out by the lifting action of each tooth. The result is a relatively flat trench bottom due to the fact that the ripper tooth tips all lie on a constant radius with a center of rotation that is close to the tractor loader backhoe or hydraulic excavator “dipper stick” bucket pivot. The DigNRip bucket will function for any application or material that a single pointed ripper tooth can be used for.

With the stick in the near vertical position, use a combination of bucket and crowd cylinder functions while providing boom cylinder down pressure. The bucket cylinder action provides the greatest force. Since no two teeth are in alignment, when the bucket is rolled, each tooth engages separately so that each tooth fractures the groove cut by the preceding tooth. Roll the bucket completely so that all teeth have engaged the material. The last tooth can also be used as a pick for stubborn spots.

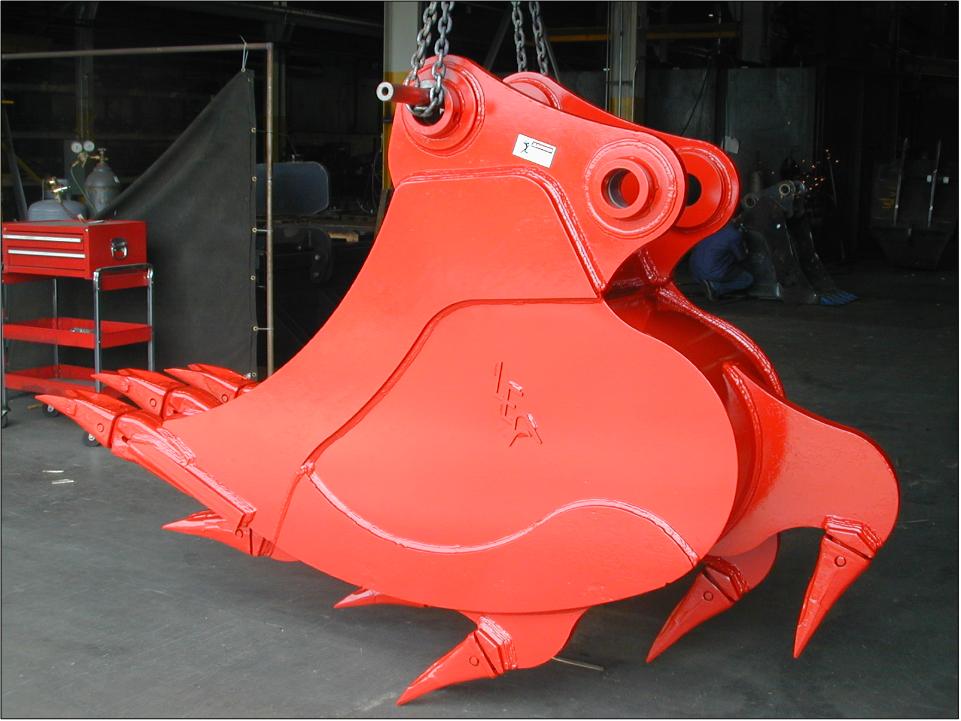

Below is DigNRip Bucket with ESCO teeth

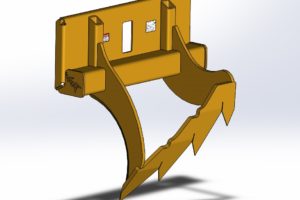

Below is a DigNRip Bucket for a Volvo S3 coupler

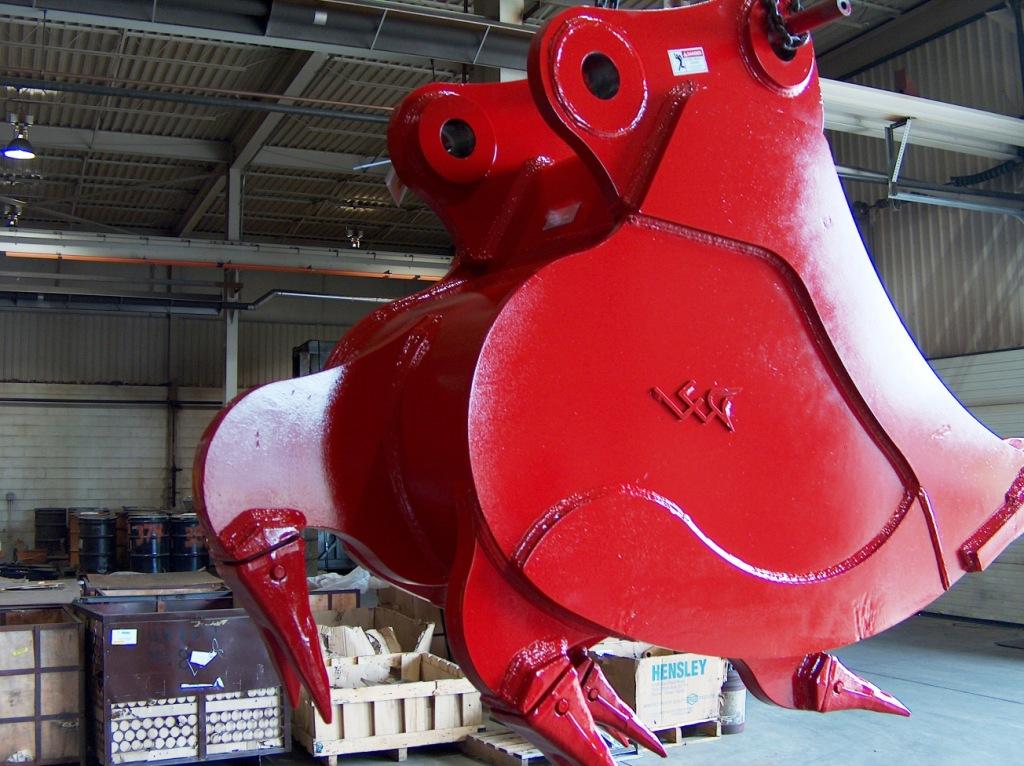

Below is a DigNRip Bucket backside with Hensley teeth

Leave a Reply

Your email is safe with us.